Screen printing, Single or Dual lane, in-line or off-line.

Low volume/High mix to High volume/High mix.

Reflow, Wave, Selective, in-line, off-line and benchtop.

Temperature profile measurement for Reflow, Wave, Selective

Conformal coating, Mixing, Potting, Dispensing.

Personnel grounding, Test and monitoring. Access control, logging.

Printer cleaner rolls, Splice tapes, Filters, Nozzles, Spare parts.

Superior benchtop convection ovens for batch reflow and laboratory use.

Hot Air systems for cost effective rework. Board pre-heaters.

PCB Holders, Tweezers, etc.

Reflow Soldering

The new HOTFLOW series from ERSA once again raises the bar when it comes to the reflow process. The design of the new ovens focused on optimising heat transfer and reducing maintenance time while increasing machine uptime and productivity.

ERSA EXOS 10/26 Voidless

Inline reflow soldering with vacuum.

- 4-part conveyor (infeed, preheating and peak, vacuum, cooling zone) also as dual track

- Perfect synchronization of the assemblies and transitions thanks to sensor-monitored conveyor, no external infeed module required

- Maintenance-friendly and lubricant-free roller conveyor in the vacuum module

- Optimum access to the vacuum chamber through lifting unit from above

- Optimum temperature profiles through medium-wave emitters in the vacuum module

- Maximum machine availability thanks to fast removal of the conveyor unit in the vacuum module

- Part-integrated vacuum pump on separate module carrier for easy and fast maintenance

- Innovative cleaning system SMART ELEMENTS®

ERSA Hotflow 4 Series

Reflow soldering with excellent performance and best energy balance.

- Individually controllable process zones via energy-optimised motors

- Multi-level controlled cooling

- Multi-level process gas cleaning with pyrolysis

- Rest-oxygen monitoring and control, low N2 consumption

- Ersa Process Control Software (EPC)

- Multi track conveyor systems (1-4), 1x fixed, 3x variable

- Thermally invisible centre supports

- Low energy consumption in continuous operation

ERSA Hotflow THREE Series - A New era in reflow

Now the industry benchmark for reflow ovens. Exclusively developed Smart Convection Power Unit integrates fan motors and controls for optimum efficiency.

- Optimal soldering quality, no matter how complex the assembly, no matter how demanding the components

- SMART CONVECTION POWER UNIT (SCPU®)

- Higher productivity with lower/minimized energy consumption

- Longer maintenance intervals due to innovative three-fold cleaning system SMART ELEMENTS®

- SMART PYROLYSIS CLEANER

- SMART CONDENSATION UNIT

- Super maintenance friendly and easy to access components minimize downtimes

ERSA Hotflow 3/14e and 3/20e

The ERSA HOTFLOW 3/14e and 3/20e ovens are energy-efficient reflow systems for highest throughput requirements. They are economically priced and give maximum value for return on investment.

- Optimised heat transfer, minimised delta T

- Internal cooling

- Automatic chain lubrication

- Automatic low mass centre support

- Multi lane conveyor system available

- Low energy consumption

- Auto profiler for rapid offline profiling

Selective Soldering

Accepted as the world leader in Selective Soldering, ERSA is now proud to introduce the fourth generation of VERSAFLOW machines. These Best In Class machines feature leading edge technologies and are modular in design and so can match the highest demands on flexibility and throughput while also fitting every budget. There is an ERSA selective soldering machine to suit everyone from the SMARTFLOW, ECOSELECT, ECOCELL to VERSAFLOW series.

ERSA VERSAFLOW 4 Series

The Ultimate is Selective soldering - Inline Selective Soldering now even better!

- Intelligent high-end selective soldering machine for inline production

- Full modularity - suitable for every customer requirement

- Tripling of throughput with highest flexibility

- Intuitive operating concept

- Highest process reliability through proven control systems

ERSA VERSAFLOW ONE

The VERSAFLOW ONE is the ONE. For everyone. Your entry into ERSA selective soldering. It is the benchmark in terms of productivity and flexibility.

- Highest quality and highest throughput with compact line dimensions

- Fast and easy program creation including stable processes for perfect soldering results

- Proven and future-proof technology from the world-leading VERSAFLOW world

- Short delivery times thanks to series production with the most popular configuration features available directly from stock

ERSA VERSAFLOW 3/35 GLOBAL EDITION

Pre-configured soldering machines with leading selective soldering technology

- Highest throughput in the entire selective soldering market

- Most sold selective machine platform worldwide

- Safe process control with monitoring of all relevant parameters

- Full modularity - suitable for every customer requirement

- Comes with a host of options included

ERSA SMARTFLOW 2020

The little big one among the selective soldering systems: uncompromisingly compact.

- "Plug and Solder" - the compact selective entry model

- Intuitive operating concept

- Large soldering area of 508 x 508mm (20” x 20”)

- Automatic solder wire feeder

- Drop jet fluxer with integrated monitoring

- Ersa CAD Assistant for easy programming

Wave Soldering

The POWERFLOW series of Wave Soldering machines are designed specifically to meet the challenges of today. Multipe preheat configurations are available to privide the best heat transfer. Multips nozzle configurations to select from to give the best soldering results. Full nitrogen tunnels, best in market control systems and easy operation and maintenance provide you with all the tools to get the best performance and quality.

ERSA POWERFLOW ULTRA

High-end full tunnel nitrogen wave soldering system. The POWERFLOW ULTRA is the ultimate solution for demanding wave soldering solutions.

- Highest flexibility, highest throughput and highest availability

- Modular, flexible and individually expandable preheating concept variably configurable in length and power

- Award-winning database-based operating software ERSASOFT 5 > Ready for Industry 4.0

- Finger and frame transport with different working widths

ERSA POWERFLOW PRO

The POWERFLOW PRO is a compact full nitrogen tunnel machine for cost-optimised wave soldering.

- Modular, flexible and individually expandable preheating concept variably configurable in length and power

- Award-winning database-based operating software ERSASOFT 5 > Ready for Industry 4.0

- Finger and frame transport with different working widths

ERSA POWERFLOW

Powerful wave soldering system with attractive price/performance ratio.

- Modular, flexible and individually expandable preheating concept - can be configured variably in terms of length and output (can also be retrofitted)

- Monitoring and documentation of all process-relevant data > ready for traceability

Temperature Profiler

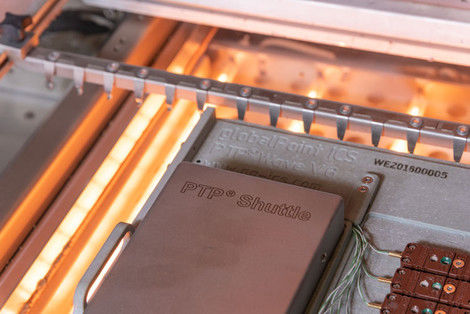

GlobalPoint ICS has been one of the leading international suppliers of measuring technology for all soldering processes for more than twenty years. Now part of the ERSA group, they are continually setting global benchmarks for precise, innovative and reliable systems as well as intelligent, user-friendly software.

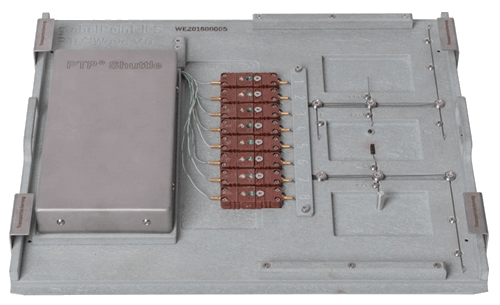

PTP® MEASURING SYSTEM

The range of Professional Temperature Profiler (PTP®) products cover measuring technology for reflow systems, vacuum/vapour phase soldering systems, wave soldering systems and selective soldering systems as well as the matching measuring boards.

In today's world of advanced, high temperature, lead-free electronics, thermal profiling is a must. It can, however, be a bewildering task: some software packages are difficult to understand and use, and their output requires a degree of interpretation that assumes long experience in profiling.

- PTP® Electronics with 8 channel + internal temperature

- Bluetooth connection, real-time profiling

- For Reflow, Wave, Selective and Vapour Phase

- Measuring range -50 to +1350 °C

- IP67 industry protection

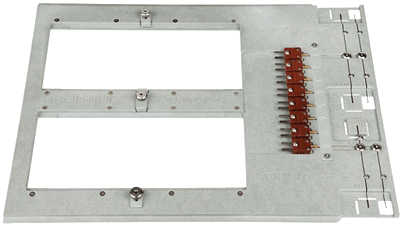

MEASURING BOARD REFLOW V5

The Reflow V5 measuring board and measuring electronics PTP® make an ideal and versatile instrument for process recording, analysis and optimisation. The measuring board Reflow V5 has eight thermocouples of the highest accuracy class. These are placed permanently on specially designed measuring fields. The measuring board Reflow V5 is used to check the system parameters as well as their optimisation in the soldering system.

All you do is run this board through your oven to record your datum profile. Then run this board through your oven periodically to verify that your oven is performing as required.

MEASURING BOARD WAVE V6

The Wave V6 measuring board is similar in operation to the Reflow measuring board. Eight thermocouples are permanently attached to specific points on hte board to measure various parameters which affect your wave soldering process.

- Measurement of the atmospheric temperature

- Measurement of dwell times left, centre and right

- Measurement of the transport speed

- Recording the energy input for evaluating the risk to sensitive components

Hand Soldering

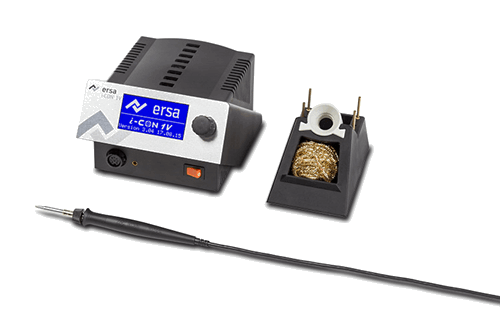

The i-CON series from ERSA are designed with one purpose, to give the best soldering results. Each tool is ergonomically designed for comfort and ease of use.

ERSA i-CON VARIO

The i-CON VARIO is perfectly suited to all SMT and PTH soldering applications in electronic production, rework and touch-up. The VARIO family of irons introduce hot air tools, solder extraction and of course de-soldering tweezers.

- Soldering and de-soldering, Two or Four tools operating at once

- Intelligent power management for dynamic power distribution

- Built-in vacuum pump for de-soldering tools

- Easy operation - intuitive one touch button button

- Anti-static design

ERSA i-CON 1 family

The i-CON 1 family is suited to all SMT and PTH soldering applications in electronic production, rework and touch-up. The attachable tools and quick tip change allow flexible usage depending on demands. Multiple configurations available including single and double tool, extraction control and nitrogen supply to the soldering area.

- Soldering and de-soldering station

- Eight different tools available including VARIO tools

- Easy operation - intuitive one touch button button

- Anti-static design

- Multiple configurations available

ERSA i-CON Nano

The i-CON NANO is an ultra-light and ergonomically designed station which still has high power output. It is fully digital and uses the same tips as the i-CON family.

- Soldering and de-soldering station

- Very small footprint (145 x 80mm)

- High power output of 68W

- Three fixed temperature settings, or changeable from 150 to 450 degrees

- Operator can be locked out, full process control

- Anti-static design

ERSA Standard Soldering Iron

The tried and proven soldering iron comes in 50W, 80W and 150W to cater for all your soldering requirements. Great for soldering copper conductors and other heavy connections. Comes with straight or bent tip.

- 50W, 80W or 150W power

- 180s heating up time

- Tips have long-life coating

- Non anti-static

ERSA Workshop Irons

The Ersa hammer soldering iron is especially suitable for sheet metal processing, installation work and for soldering commutators and copper bus bars. It is ideal for any heavy soldering which requires high power. Hammer soldering irons have also proven their merit in automotive body adjustments and lead glazing.

- 200W, 300W and 550W available

- Long life tip

- Non anti-static

ERSA Solder Baths

ERSA also manufacture static solder baths which are used to pre-tin components, wires etc. To increase the soldering quality we recommend the use of our temperature regulator as it also reduces oxide formation and saves energy. There are many different sizes of pot available so please contact us for further details.

For more than 20 years now, thousands of users worldwide have used ERSA's patented IR and Hybrid-Rework technology. Offering fantastic price/performance ratio, ERSA systems continue to be the benchmark.

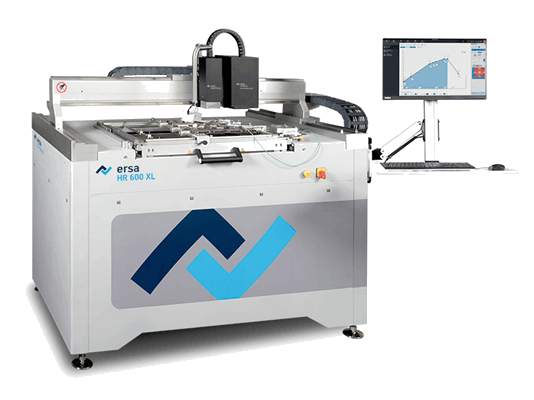

ERSA HR 600 Series

The award-winning ERSA HR 600 Series systems come in different configurations to suit your applications. The HR 600 Series systems offer automatic rework with as much manual input as you wish. All systems use the ERSA patented Hybrid rework technology, no component specific nozzles are needed offering full flexibility, and keeps costs down.

- For small chips/fine pitch

- 01005 to 60 x 60 mm

- High precision axis system

- High resolution cameras

- 3,200W heating capacity

- Automated rework

- Automated rework, repeatible

- 3,200W of hybrid heating capacity

- Highly accurate X, Y and Z axes

- Dip and Print station available

- Low running cost, no specific tools

- Process control & documentation

- Large board rework (625 x 625mm)

- Up to 17,000W heating capacity

- Highly accurate X, Y and Z axes

- Repeatable results guaranteed

- Fully automatic or semi-automatic

- Dip and Print station available

ERSA HR 550 Series

The new HR 550 is another award-winning rework systems from ERSA. Designed to be flexible and offer high-perfromance, it is the best first step into semi-automated rework.

- 4,200W heating capacity

- Up to 400 x 300mm board size

- Computer aided rework alignment

- Enhanced visual assistant

- 3Process control & documentation

- Suitable for Dip & Print station

- Budget-orientated system

- 2,500W of hybrid heating capacity

- 380 x 300 board size

- Dip and Print station available

- Computer-aided rework alignment

- Modern user-friendly software

- Large board rework (610 x 530mm)

- Up to 8,200W heating capacity

- High resolution cameras

- Computer-aided rework alignment

- Optimal ergonomics

- Dip and Print station available

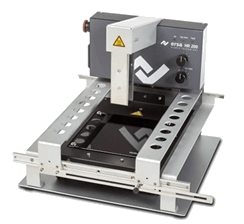

ERSA HR 200

Simple and fast desoldering and soldering of SMD's.

Rework straight out of the box!

- 400W of heating capacity available

- Additional 800W heating plate optional

- Very short soldering times feasible

- Footswitch activated

- Intuitive operation without software

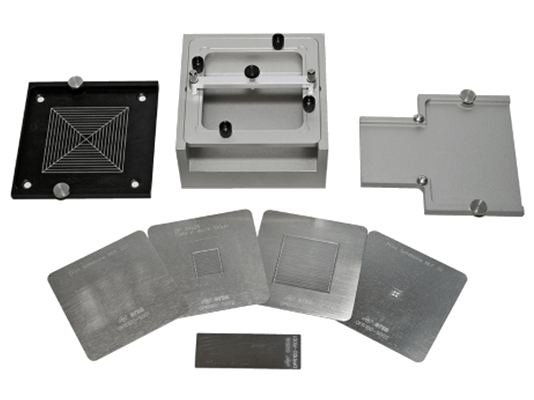

ERSA Dip and Print Staion

The Dip & Print Station is suitable for use with all ERSA rework systems. Simply print on the component or dip the component into your process material to specific depth.

- Simple, reliable & repeatable

- Prepare your components with paste or flux

- Component specific stencil according to requirements

- Adapters for all ERSA systems, one system for all

ERSA FUME EXTRACTION

The ERSA EASY ARM 2 family of solder fume extraction units provide a clean and healthy environment for the operator doing any soldering operations.

- Efficient 3-stage particle and gas filtering

- Super silent operation

- Single arm and Double arm systems available

- On/Off can be controlled by your ERSA soldering iron or rework system

- Optical and acoustic alarm for filter change

Robot Soldering

The new ERSA SOLDER SMART SR500 uses the powerful i-TOOL which provides 150W of soldering power. Multi-axis system offers full control and repeatability to ensure high quality results.

ERSA SOLDER SMART SR500

The new SR500 offers high quality repeatible soldering at a cost -effective price to our customers.

- Soldering tips from 0.4mm to 5mm wide tips

- High axis accuracy +/- 0.02mm

- Spot soldering, line soldering, drag soldering

- Precise, reliable solder wire feeder

- Complete process monitoring

- 500mm x 400mm working area, flexible

- Or 240mm x 382mm with tables

Benchtop Batch Oven

The New X-Reflow306 LF series is a bench top, convection batch oven which is also nitrogen ready and designed for Lead Free soldering. High-performance, low-cost for small lot production and laboratory use and simulation tests.

X-KAR X-Reflow306 LF

The X-Reflow306 LF-AC is the only oven on the market which meets the new test procedures for PCB laminate manufacture. The oven can simulate 6 or 8 (changeable) reflow cycles with accelerated cooling between cycles to room temperature with minimum operator intervention.

- Full convection heating with independent control of front and rear heaters

- Large inspection window allows monitoring of the reflow process

- Microprocessor control ensures temperature profile repeatability

- Computer interface allows control of programming and operation

- Small desktop footprint, weighs only 45kg

- Nitrogen port for inert soldering if required

For more information go to www.x-reflow306.com

Rework

Cost-effective rework systems for repairing boards during their assembly and servicing them after sales. Good and reliable tools are needed to complete these operations and must be easy to use.

The X-FineRework systems are modular digital PID control SMT rework/repair systems with pre-heater,

- Profiling capabilities for time/temperature

- Repeatable process from board to board

- Large area board pre-heater for up to 14" pcb

- Selection of standard, lightweight nozzles

- Fully anti-static, comes with wrist strap etc.

- Self-contained air and vacuum sources

- Modular system, can be added to in future

For more info visit www.smtrework.com

Powerful and cost efficient medium and small size area pre-heaters. A must for safe rework/repair of any multi-layer board.

- In-built "K" thermocouple for verification

- Microprocessor controlled

- Closed loop temperature PID control

- ESD safe, supplied with arist strap

For more info visit www.smtpreheater.com

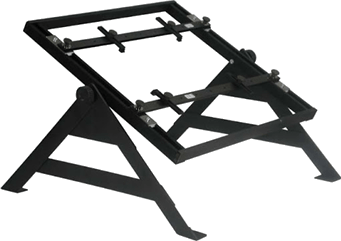

- Static and rotating board holders

- Board size from 25mm to 350mm

- Spring-loaded tooling for quick exchange

- Basic board holders and supports

- All size of tweezers available

- Screwdrivers, pliers, snips

- BGA re-balling

- Solder iron tip cleaners

- Solder reel holders

- Vacuum pick systems

23 The Downs, Broadale, Douglas

Cork T12V3FR, Ireland.

+353 87 8101820

sales@prime-option.com