SAKI 3Di-LS3

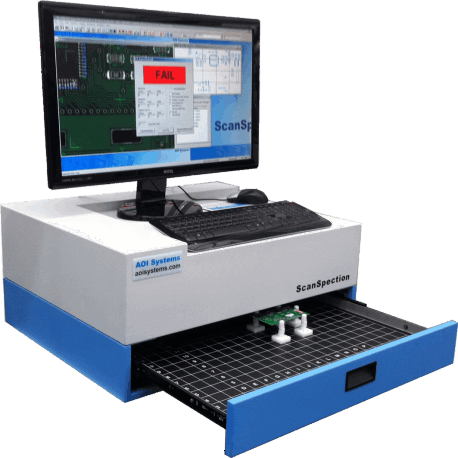

Just as with 2D AOI, Saki has been in the forefront of 3D AOI development. Saki has now introduced its 3rd generation AOI systems. These flexible and adaptable, high-quality, cost-effective systems can be used for simple verification to full algorithm-based measurements.

The call for more stringent standards for surface mount devices and the need to identify defects of 1-10 ppm or less to improve yield, process control, and quality assurance, led to the development of 3D automated optical inspection (AOI).

- New hardware design to improve frame rigidity for stable and repeatable reults

- Four stage lighting for optimum illumination and better image capture

- True height measurement with a range of up to 20mm

- Automatic tuning of the inspection algorithms

- Saki Self Programming for simple, easy time-saving programming

- Extra Component Detection to improve quality