Dispensing/Coating

Selective Conformal Coating, Potting, Dispensing, Fluid Mixing/Metering/Dispensing, Curing, Handling

Conformal Coating materials, Adhesives, Encapsulation, Thermal Management

Selective Conformal Coating, Potting, Dispensing, Fluid Mixing/Metering/Dispensing, Curing, Handling

Conformal Coating materials, Adhesives, Encapsulation, Thermal Management

PVA equipment can be used for a diverse array of applications from dispensing Adhesives and Sealants to Selective Conformal Coating of PCB’s to dispensing Potting materials, be they single or multiple part. PVA can also supply curing solutions for all the above so a full turnkey solution is available with full process support.

PVA DELTA 8

Ideal for selective coating, potting, bead, and meter-mix dispensing applications, the Delta 8 is designed for maximum flexibility and can also be configured for custom assembly applications.

Maintaining the preferred features of previous workcells, the Delta 8 features a robust overhead three-axis motion platform suitable for inline or batch operations. Improved structural and gantry rigidity have been added for robustness and easier access.

The Delta 8 has many options and integrated features including:

- Robotic system repeatability of 25 microns

- Patented servo-controlled optional four-axis motion featuring valve tilt and rotate

- Closed loop process control throughout gantry system

- Multiple dispensing applications or materials in one cell

- Onboard PC for unlimited program storage

- Exclusive PathMaster® programming environment

- Multiple configurations possible including additional axes

- Conveyor type: 600 x 500 working area

PVA DELTA 6

The Delta 6 features a robust overhead three-axis motion platform suitable for inline or batch operations.

While maintaining the preferred features of previous workcells, the Delta 6 has been designed with a slimmer footprint, improved structural and gantry rigidity for robustness, and easier access.

The Delta 6 has many options and integrated features including:

- Robotic system repeatability of 25 microns

- Patented servo-controlled optional four-axis motion featuring valve tilt and rotate

- Closed loop process control throughout gantry system

- Multiple dispensing applications or materials in one cell

- Onboard PC for unlimited program storage and Programming Camera

- Exclusive PathMaster® programming environment

- Servo 4th Axis motion featuring valve tilt & rotate

- Closed-loop material flow monitoring

- Inline material metering

- Bar code program selection

- Low level fluid sensor

- Valve and / or fluid heating

PVA SIGMA

The Sigma benchtop is a compact three-axis robotic gantry ideal for automating a variety of dispensing and coating applications. Featuring multiple mounting positions, users can easily incorporate multiple chemistries or application techniques into their process.

With remote programming capability and image background import, programs can be quickly uploaded from your desktop utilizing Sigma’s internal 2.4 GHz Wi-Fi network.

Sigma combines PVA’s superior quality and global support in a flexible, multi-purpose robot that instantly brings repeatability to your manufacturing process.

The Sigma benchtop has many options and integrated features including:

- 5-inch touch interface with Wi-Fi connectivity

- Offline G-code numerical control programming

- Enclosed work area with safety interlock

- Single or dual valve mounting positions

- Standard jig plate mounting surface

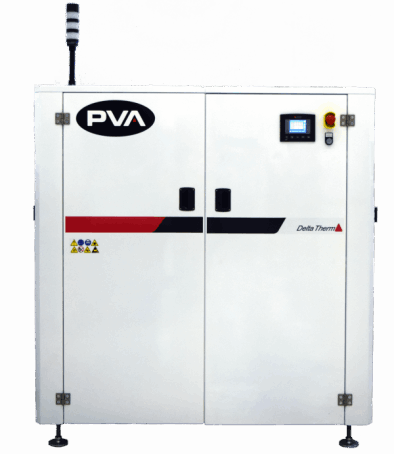

PVA DELTATHERM

The DeltaTherm features a double-sided configuration available in 4’ and 8’ curing lengths. The DeltaTherm offers custom heat profiling in each two foot section. Each infrared, coated panel is constructed for easy cleaning and maintenance. The DeltaTherm has many integrated features including:

- Edge carrying, variable speed pin chain

- Conveyor rail expansion compensation

- SMEMA communications interface

- Four-inch top and bottom side component clearance

- Thermocouple process control with independent over temperature protection

For further information please contact us.

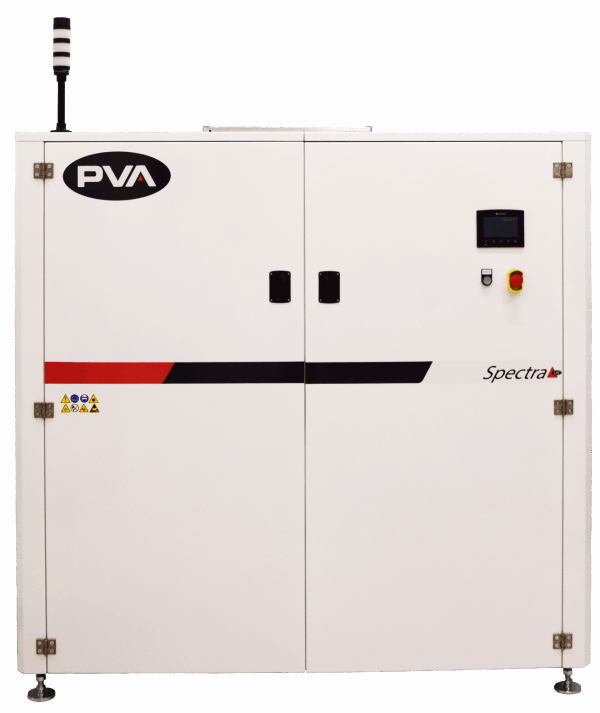

PVA SPECTRA

Spectra features Fusion® UV lamps to initiate fast ultraviolet light polymerization of adhesives and coatings in an efficient inline process. Various beam widths are available to accommodate a wide range of substrate dimensions.

Some of the Spectra features include:

- Unitronics PLC Controller with OIT touch screen interface

- Single or double-sided processing

- Dual zone conveyor with configurable cure and transfer speeds

- SMEMA edge carrying chain conveyor with SMEMA communications interface

- Maximum 4" top and bottom side component clearance

- Optional automatic conveyor width adjust

- Fully enclosed for clean and quiet operation

- Large access doors to all critical areas Inlet air filtration system

- Rail expansion compensation

PVA also offers a wide range of manual solutions for conformal coating and dispensing:

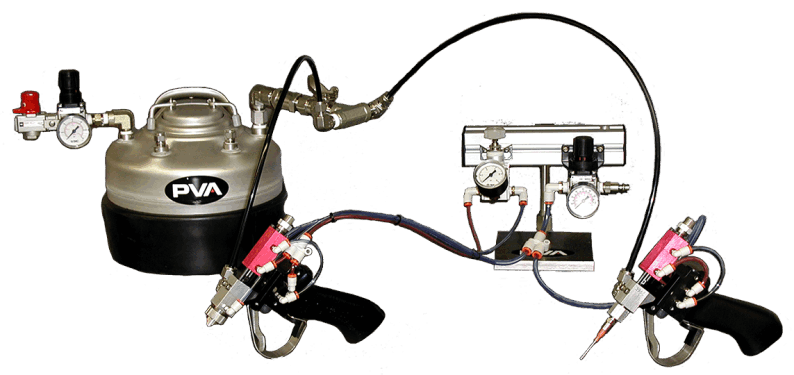

PVA MCCS-SYS-1

The MCCS-SYS-1 is a turnkey manual conformal coating system that utilizes a spray valve and dispense valve to selectively apply coatings to a circuit board. With an all stainless steel and Teflon construction this system can be used to hand le a wide variety of fluid chemistries.

- One spray valve to apply coating to large areas

- One dispense valve to apply coating close to keep out areas

- Trigger finger activation for ease of control

- Single large tank to hold up to 1-gallon of fluid

- Stainless Steel & Teflon wetted components for fluid compatibility

- Pneumatically operated system

- Easy cleanup and shut down

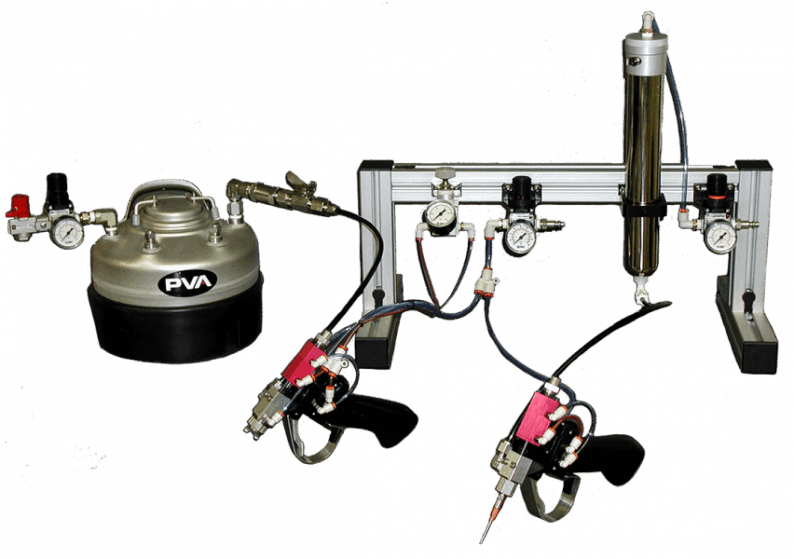

PVA MCCS-SYS-2

The MCCS-SYS-2 is a turnkey manual conformal coating system that utilizes a spray valve and dispense valve to selectively apply solvent based coatings to a circuit board. With an all stainless steel and Teflon construction this system can be used to hand le a wide variety of fluid chemistries.

- One spray valve to apply solvent based coating to large areas

- One dispense valve to apply thicker coating close to keep out areas

- Trigger finger activation for ease of control

- Large tank to hold up to 1-gallon of fluid for spray

- Smaller cartridge reservoir to hold up to 12 oz. of fluid fro dispense

- Full pneumatically operated system

- Easy cleanup and shut down

PVA ST100S

The ST100S is a digital shot timer used for syringe dispensing. This compact controller is an economic and ergonomic solution for improving the waste, inaccuracies, and clean up associated with many manual processes. The ST100S is ideal for chemistries packaged in syringes such as solder paste, UV adhesives, and masking material.

- Digital timer with LED display and 0.001 – 99.99 second time range

- Manual, timed, or teach modes

- Adjustable analog vacuum suck-back for clean cycle stops

- Integrated pressure control

- Electric foot pedal and power cord

- Built in regulator and gauge

PVA RD100

This simple dispense system uses a single stepper motor on the base to rotate a part as the dispense head above accurately applies a bead of fluid. Flexibility and adjustment of the dispense head, rotation angle, and programmable control interface allow this simple dispense system to apply seamless beads of adhesives and sealants.

- Lightweight tabletop design that favors portability

- Fully programmable revolution speed and degree of revolution

- Integrated controls to operate syringes, cartridges, or valves

- Ability to mount syringes or any other valve

- Dispense valves can be fed from any reservoirs

- Adjustable z-axis with tilt

- Pneumatic z-slide travel of 50 mm (2 in)

- Push button or foot pedal activation

- Single and dual rotary tables available

HumiSeal is a division of Chase Corporation and produces conformal coatings from all chemistries, including acrylics, urethanes and silicones, both water based and UV curable. This represents the largest product range and the widest choice of qualified products available. HumiSeal are always at the forefront of conformal coating innovation and product development. This means that HumiSeal can meet all your requirements while constantly striving to stay one step ahead as your business develops.

As well as conformal coating materials, HumiSeal also produces Adhesives, Encapsulation and Thermal Management materials.

HumiSeal ACRYLIC

Acrylic conformal coatings are perhaps the most popular of all conformal coating materials as they are easy to apply and remove, with a wide process window for use. Acrylic coatings dry rapidly, are fungus resistant and provide long pot life. Additionally, acrylic materials produce little or no heat during the curing process, eliminating potential damage to heat sensitive components. The coatings possess low shrinkage, provide significant humidity resistance and exhibit low glass transition temperatures.

HumiSeal POLYURETHANE

Polyurethane coatings are available in either single or two-component formulations. Both options provide excellent humidity resistance and far greater chemical resistance than acrylic coatings. Single component polyurethanes, while easy-to-apply and enjoy long pot life, sometimes require long curing regiments to achieve a full or optimum cure. In some instances, the cure cycle can be accelerated with the application of heat.

HumiSeal UV

HumiSeal's UV curable conformal coatings represent an exciting innovation that provides superior performance. When combined with extremely fast curing, allows for short cycle times and maximum production speeds. These products can be sprayed using traditional automated spray equipment with the relatively simple addition of a small-footprint UV light curing unit.

HumiSeal Synthetic Rubber

HumiSeal’s Synthetic Rubber products are unique formulations that may enable the user to achieve specific protection / environmental goals not offered by “traditional” coatings. Synthetic Rubber materials are characterized by extremely low glass transition temperatures, resulting in stable modulus over a wide temperature range and extreme flexibility. Synthetic Rubbers have the least moisture permeability of all resins currently available. These products do not necessarily represent our complete Synthetic Rubber range.

HumiSeal Silicones

Silicone conformal coatings are most widely used in high-temperature environments due to their innate ability to withstand prolonged exposure to higher temperatures than most other conformal coating chemistries. This attribute has made them the primary choice for under hood automotive applications. They are also capable of being applied in thicker films making them useful as a vibration dampening/isolation tool if the coated assembly is to be placed in a high vibration environment.

HumiSeal WATER-BASED

Water-based conformal coatings, by their very nature, are extremely safe, low odor, low VOC products, developed to enable customers to meet the ever-stricter emissions targets, not to mention the various health and safety requirements. It enables enormous reductions in VOC emissions, especially in the automotive sector. These products are based upon the standard chemistries of Acrylic, and Polyurethane, offering the closest match in protective performance to the existing solvent-based conformal coating range.

General purpose adhesive or encapsulant. Medium viscosity with 1:1 mix ratio. Medium hardness with good flexibility. A wide range of applications with bonding capabilities to multiple substrates.

Chemistry: Urethane

Pot life (min):<8

Substrates: Metals, Hard to bond Plastics, Glass, Ceramics, PolyCarb, Electronics

General purpose adhesive or encapsulant. High viscosity with 1:1 mix ratio and long work life. Medium hardness with good flexibility. A wide range of applications with bonding capabilities to multiple substrates

Chemistry: Urethane

Pot life (min):30

Substrates:Metals, Hard to bond Plastics, Glass, Ceramics, PolyCarb, Electronics

Epoxy adhesive or encapsulant with a range of mix ratios and hardness resulting in high bond strength to a variety of materials. Very good electric insulator, resistant to gasses, water, petroleum products, and acids. FDA compliant.

Chemistry: Epoxy

Pot life: 69 min

Substrates:Metals, Glass, Ceramics, Plastic

HumiSeal ADHESIVE SOLUTIONS

HumiSeal adhesives are used to bond a variety of materials capable of withstanding mechanical shock, electrical exposure, and severe weathering. These are formulated from urethane or epoxy and are effectively cured with UV light, heat, or at ambient temperature. If your application requires a set of properties that are not available in standard product portfolio, HumiSeal can provide a custom solution. Please contact us for further assistance or visit HumiSeal web-site.

Resin Designs ® connector seal grommets and sealing strips provide sealing and corrosion protection for indoor and outdoor equipment, including connectors and electrical components. The material is cold-applied like conventional tapes and grommets or gaskets, yet it has sealing capabilities similar to high-performance potting compounds and is superior in conformability to traditional elastomeric gaskets.

With the increase in processing power, charging wattages and the trend toward smaller, more compact electronic modules, transfer of thermal energy to heat sinks, cooled chassis and other safe locations is essential in maintaining component temperatures within operating specification limits. Resin Designs’ family of thermal interface pads provide superior performance with a variety of thermal pad constructions.

Long-term, reliable protection of sensitive circuits and components is important in today’s delicate and demanding electronics applications. Resin Designs shielding gaskets and Resin Designs gel rope gaskets are designed to deliver by providing shielding and effective grounding of high energy electromagnetic interference (EMI). Resin Designs conductive gaskets provide dependable, cost-effective corrosion protection for aircraft skin and antennas.

Thermal gels and encapsulants offer the most flexibility in formulating to a flowable or non-flow product that fully cures to soft gel or firm elastomer for long term stability in thermal cycling. ThermoSink can be used as a TIM between component and heat sink, or assemblies can be encapsulated for optimum thermal management. Most are offered in a two-component 1:1 mix ratio package for automated meter-mix and dispensing.

23 The Downs, Broadale, Douglas

Cork T12V3FR, Ireland.

+353 87 8101820

sales@prime-option.com

Designed with Mobirise

Free Offline Site Builder